Tech news

5 steps of operation process of automatic Bag Filter central dust collection system

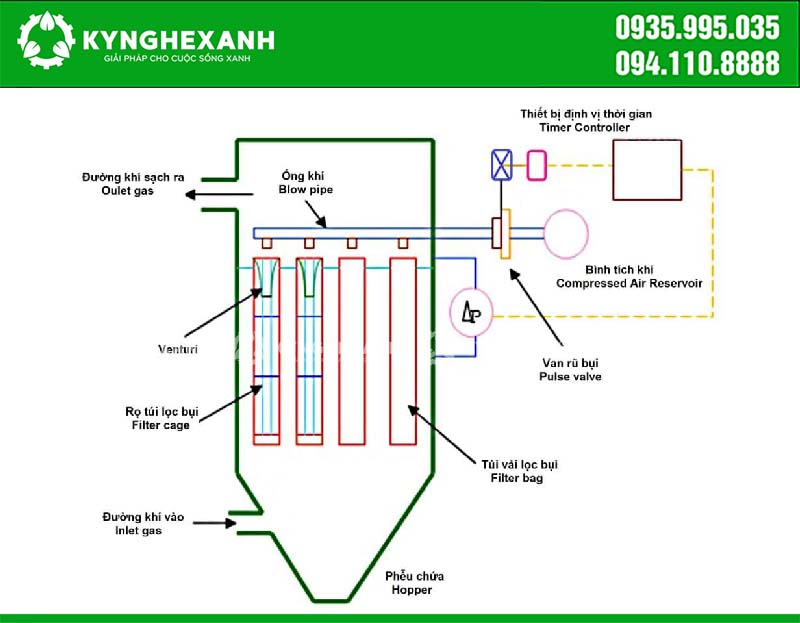

The operation process of the central dust treatment system Bag Filter ensures that the system is operated in accordance with the technical requirements and promotes the efficiency of dust treatment as well as ensures the durability and safety of the dust bag handling equipment. filter. Through this article, GREEN MECH introduces you to 5 steps in the operation process of the central dust treatment system.

MỤC LỤC

Check the dust treatment system before operation

Check the mechanical part first

- Check for grease in moving mechanism ball bearings such as screws, rotors, vacuum cleaners, and other mechanisms that use ball bearings.

- Check the tension of the exhaust fan belt by pressing down to see the sag and elasticity of the belt.

- Visually inspect external structures prior to operation.

Check control electrical part and electrical equipment

- Check the 3 phase indicator lights of the electrical cabinet.

- Check the electrical signal lights to make sure they are enough to operate the machine.

- Power on the power sources of the attached equipment.

- The voltage is sufficient to operate the machine and its attached equipment.

- Check if the warehouse screw signals are on or not.

- Check the cap sensor signal.

- Check the rinse time device setting.

5 steps of the operation process of the central dust collection system Bag Filter

When the bag filer is operated in manual mode

- Step 1: Turn on the main CB of the control cabinet

- Step 2: Turn the switch of the devices on the electrical cabinet to manual mode.

- Step 3: Open the air compressor and check the compressed air pressure gauge.

- Step 4: Press the status buttons in ON mode to run the devices according to the sequential operation procedure.

- Step 5: Specialize in OFF mode when no longer in use.

When the bag filter device works in automatic mode

- Step 1: Turn on the main CB of the control cabinet

- Step 2: Turn all devices on the electrical cabinet to Auto mode

- Step 3: Select the Auto working mode of the central bag filter dust treatment system.

- Step 4: Select to start the dust treatment system.

- Step 5: Select stop when you want to end the dust treatment process.

Stopping the dust removal system

- Step 1: Turn off the dust extraction fan.

- Step 2: Turn the Auto switch to the Off position.

- Step 3: Switch all modes of equipment on the electrical cabinet to OFF.

- Step 4: Clean the system to avoid explosion.

- Step 5: Turn off the main CB of the electrical cabinet before the end of the shift.

Notes in the operating procedure of the dust treatment system

- Empty the dust bin at the end of the day or at the end of the shift.

- During welding, cutting near the dust treatment system, absolutely do not turn on the exhaust fan, which will damage the cloth bag and cause a fire.

- If you go into the storage bin for repair, use the safety lock switch to the OFF position, leave the board under repair and have someone stand outside.

- Use manual mode only when inspecting equipment or commissioning dust collection systems.

- Move the switches to the off position when stopping manual mode.

- Always start the exhaust fan before the dust removal system operates.

- After receiving the start signal of the exhaust fan, the machine will automatically turn on the conveyor screws and the central dust treatment system.

- Record inspection data in the operation log book to monitor and control problems.

- There is a schedule to check and maintain the machine daily, weekly and monthly.

- Regularly check the working condition of the exhaust fan to ensure durability.

For all inquiries and quotations for https://kynghexanh.com.vn , please contact Tel (Zalo): +84 94 110 8888 , we will support you in the most detail.