GREEN MECH straw crusher – 2-roller straw crusher, grinding a variety of materials

1,200 $ 1,000 $

The dual-axle design enhances durability and reliability, reduces failure rates and provides flexibility for processing different types of materials. This means that the machine can flexibly adapt to many different applications, meeting the diverse needs of users. At the same time, the machine’s high performance helps optimize time and effort during the processing process, making the 2-shaft straw mill an important tool for modern businesses and farmers.

The 2-shaft grinding technology straw crusher plays an important role in the agricultural and livestock industries, helping to optimize the handling and processing of straw. With the ability to crush and cut straw into small pieces, the machine not only increases the efficiency of making animal feed but also aids in fertilizer production and mushroom growing.

The dual-axle design enhances durability and reliability, reduces failure rates and provides flexibility for processing different types of materials. This means that the machine can flexibly adapt to many different applications, meeting the diverse needs of users. At the same time, the machine’s high performance helps optimize time and effort during the processing process, making the 2-shaft straw mill an important tool for modern businesses and farmers.

The 2-shaft straw crusher is designed with a flexible capacity from 1 to 5 tons, providing a flexible solution for the diverse production needs of both farms and livestock enterprises. This flexibility not only helps optimize productivity but also ensures efficiency in handling large amounts of straw.

With the integration of conveyor belt, this crusher offers convenience in moving and arranging processed straw. Conveyors not only help optimize the process of transporting straw to different usage locations, but also ensure that the production process takes place continuously and effectively. This creates a coherent operating system, helping businesses save time and effort in the process of processing and using straw.

Main structure of 2-shaft straw crusher

- Main shaft: This is the main component responsible for the grinding process. The main shaft is usually made from high-strength alloy steel, machined with high precision to ensure good performance and mechanical durability.

- Movable blade and fixed blade: Movable blade and fixed blade are placed on the main shaft to perform the process of crushing and cutting straw into small segments.

- Reducer: The reducer helps adjust the rotation speed of the main shaft, optimizing grinding performance.

- Motor: The motor provides power to the crusher to carry out the crushing and cutting process.

- Feeding hopper: The hopper is used to load material into the crusher, starting the processing process.

- Discharge port: The discharge port is where the processed material is taken out of the machine.

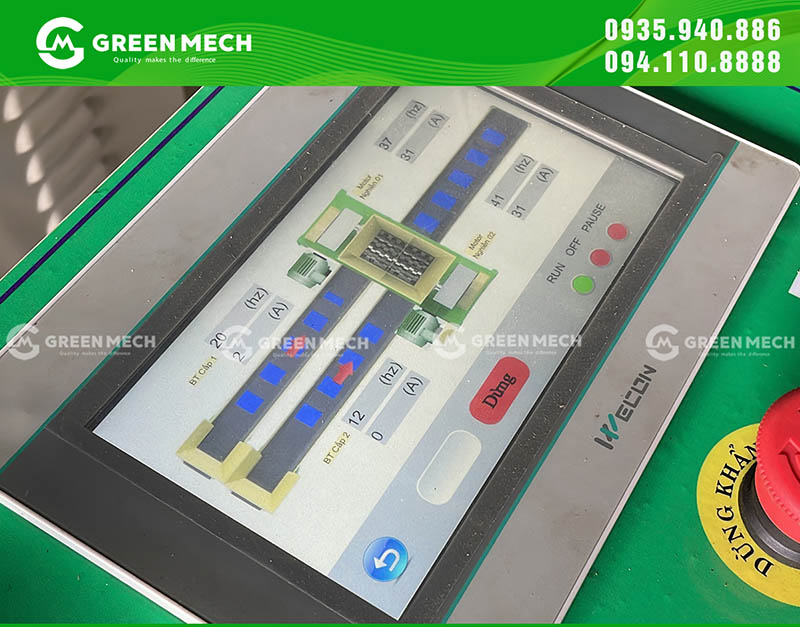

- Electrical control cabinets and control panels: Electrical control cabinets and control panels contain components and control panels to control and regulate machine operations.

- Screen: The screen displays information and data related to the grinding process and sensors.

- Roller: The roller holds and pushes the material to the grinding area, ensuring a coherent grinding process.

- Knife holder: The knife holder holds the grinding blades and ensures they operate efficiently.

The 2-roll straw mill, with its compact structure and components, is capable of processing straw effectively, reducing material size, and meeting diverse production needs in the agricultural and livestock industries. feed.

2-roll crusher crushes a variety of materials

The 2-shaft straw crusher can also process and grind a variety of waste types, bringing great efficiency and convenience in the recycling and waste reduction process. Industrial waste, such as waste from manufacturing plants and residue deposits, can be crushed for recycling and reduced environmental impact. Household waste, along with kitchen waste and waste from other sources, can be processed to reduce volume and optimize treatment.

Raw materials from wood and plants, such as twigs, leaves, straw, corn cobs, and tree trunks, can also be processed by dual-roll mills to create raw materials suitable for energy production and food production. livestock or wood recycling. Fiberglass and plastic, widely used in industry and manufacturing, can also be crushed for recycling and reuse.

The 2 shaft crusher is capable of processing waste tires, waste paper, plastic bottles, and aluminum, contributing to the recycling process and reducing waste. It can also destroy documents, computers, hard drives and substandard products, ensuring information security and e-waste management.

Videos introducing and operating the 2-shaft straw crusher

Why should you choose GREEN MECH’s 2-shaft straw crusher:

Stable operation: The powerful motor helps the crusher operate stably, without interruption, and maintain stable performance for a long time. This is especially important when processing a variety of materials.

High productivity: Powerful motor provides high productivity, helping to increase efficiency in material handling and grinding. This helps save time and energy, while optimizing the work process.

Diversity of applications: The ability to process many different types of materials is an important advantage of the GREEN MECH 2-roll mill. This makes the crusher suitable for many different industries, including recycling, construction, and manufacturing.

Easy to operate: The simple design of the crusher makes it easy to operate and manipulate. This means that users do not need to have advanced technical skills to operate the machine, and it can be used by those who are new to industrial machinery.

Easy maintenance: The crusher’s simple design makes maintenance simpler. This helps prolong the life of the machine and ensures that it always operates efficiently.

Convenient cleaning: The mill is designed for easy routine cleaning, especially important when processing a variety of materials. Regular cleaning helps ensure that the machine always operates at maximum efficiency.

Environmentally friendly: GREEN MECH 2-roll crusher is popular in the recycling industry because of its ability to minimize environmental impact. The effective recycling and disposal of materials such as waste and scrap helps reduce waste and protect natural resources.

Contact us for advice and quotes on GREEN MECH 2-shaft crusher

GREEN MECH Vietnam provides a line of 2-shaft crushers with many different capacities, and is always ready to advise customers to choose the appropriate machine and many other types of machines such as GREEN MECH wood crusher, GREEN chopper. MECH, knife sharpener,… with enterprise scale. Using GREEN MECH pellet presses helps optimize wood resources and brings high business efficiency.

For detailed advice, please contact Hotline: 094.110.8888 or visit website: https://kynghexanh.com for support.

Block "iso" not found

How useful was this post?

Click on a star to rate it!

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.

Kỹ Nghệ Xanh Việt Nam –

GREEN MECH straw crusher – 2-roller straw crusher, grinding a variety of materials high quality