Vacuum frying machine 105 kg

1,200 $ 1,000 $

During the vacuum frying process, the amount of frying oil will be lost very little compared to conventional frying methods. This occurs due to the difference in pressure between the inside of the product and the pressure in the vacuum frying pan, which helps remove oil from the surface of the product during the final stages of the frying process. As a result, fried products will have less oil, helping to create crispy dry products that still retain their delicious taste and attractive color.

SUNSAY’s 105 kg vacuum fryer is an advanced equipment used to fry fruits, vegetables and dry foods. With modern technology, this vacuum fryer allows us to quickly fry all kinds of ingredients while still retaining the product’s natural color and flavor.

The vacuum frying process in the SUNSAY machine is done to achieve crispy dry results effectively and quickly. By creating vacuum pressure, this process helps reduce the boiling temperature of water contained in the material. As a result, the frying temperature is reduced while still ensuring the water evaporation rate in the product. This process helps remove moisture from the product and produces dry, crispy products of remarkable quality.

Characteristics of vacuum frying method

During the vacuum frying machine process, the amount of frying oil will be lost very little compared to conventional frying methods. This occurs due to the difference in pressure between the inside of the product and the pressure in the vacuum frying pan, which helps remove oil from the surface of the product during the final stages of the frying process. As a result, fried products will have less oil, helping to create crispy dry products that still retain their delicious taste and attractive color.

Besides, the low-temperature vacuum frying process helps maintain the natural color of the product. Thanks to the use of low temperatures, fried foods such as dried fruits, dried vegetables, and dried cashews retain brighter and more natural colors than conventional frying methods. This also helps retain important nutrients, vitamins and minerals in the product, limiting loss.

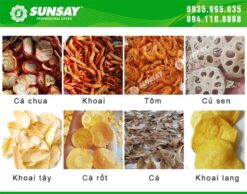

SUNSAY 105 kg vacuum fryer is a multi-purpose device, suitable for frying a variety of foods such as dried fruits, dried vegetables, dried cashews and many other ingredients. Vacuum frying technology helps retain the natural nutritional values available in ingredients such as vitamins, natural color compounds, carbohydrate compounds and micronutrients.

At the same time, using low temperature during the frying process helps the product retain its crispy texture and attractive color, increasing the sensory value of the product. Furthermore, the vacuum frying process also reduces adverse effects on the quality of the oil used, providing better results for fried products.

Outstanding features of SUNSAY 105 kg vacuum fryer

SUNSAY’s vacuum fryer with 105 kg capacity is designed with a sealed frying system to create vacuum pressure. This helps minimize the rate of waste during the frying process and saves frying oil compared to traditional open frying technology.

This vacuum frying machine is automatically controlled by an electronic control system, allowing users to easily set the temperature and frying time. High-end and quality imported electrical devices are used in the machine, ensuring high performance and reliability.

The entire vacuum frying machine is made of Stainless Steel 304, a stainless material that is reliable and safe with food hygiene standards. This ensures that the fried product is free from bacterial contamination and meets food safety requirements.

The vacuum fryer is designed to be durable, sturdy and seamless, and is easy to install, transport and has a compact size. This helps save factory space and creates favorable conditions for use.

How to fry fruits and foods with a vacuum fryer

- Prepare the products to be fried and place them in 4 small baskets.

- Place the baskets in the fryer inside the fryer and close the door.

- Start the machine and set the time and temperature parameters for the frying process. Then, turn on the machine for it to work.

- The machine will automatically vacuum and heat the oil inside the frying chamber.

- When the temperature and vacuum pressure are sufficient, the mechanism in the machine will allow the product to come into contact with the oil and begin the frying process. For automatic processes, the process happens automatically.

- Users can also monitor the frying process through transparent glass and can operate it manually through buttons on the electric control cabinet.

- When the frying time is enough, the ingredients will be lifted from the oil surface and then the machine will automatically release the vacuum and open the door.

- The user can now take the product out and put it in a centrifuge to separate the oil from the product. The centrifugation process will help separate the oil from the product, and after centrifugation is complete, the product is complete without oil remaining.

- Finally, after the vacuum frying process, the oil-separated product will be packaged using a vacuum machine or bag sealer to preserve and ensure the quality of the vacuum fried product.

Quotation for vacuum frying machine

If you need any advice or quote for the vacuum frying machine, please visit the website: kynghexanh.com.vn or contact Phone number (Zalo): +84 94 110 8888 and we will support you promptly. most detailed.

How useful was this post?

Click on a star to rate it!

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.

Kỹ Nghệ Xanh Việt Nam –

Vacuum frying machine 105 kg high-quality