Tech news

What is wood chips? How is the production process of high quality export wood chips?

What is wood chips? How is the production process of high quality export wood chips ? Through this article, GREEN MECH Wood Chipper will give you an overview to better understand the technology and equipment for processing high quality export wood chips.

MỤC LỤC

What is wood chips?

From timber trees such as acacia wood, eucalyptus wood, mixed wood, …. by processing wood materials into commercial products for export, furnace, pellets, pressed firewood or biological cushions. for high-tech agricultural production. Shredded pieces of wood less than 1 to 3 cm in size are called wood chips.

However, in order to be able to produce a large amount of woodchips for export every day, proactively applying technology to create high-quality wood chips has also been applied more commonly. From the branches and trees, people have applied a processing line according to the synchronous production process of wood chips with high quality and a large capacity wood chip machine, in a matter of seconds it was possible to produce the output of wood chips. very fast, guaranteed export standards and efficient.

How is the production process of high quality export wood chips?

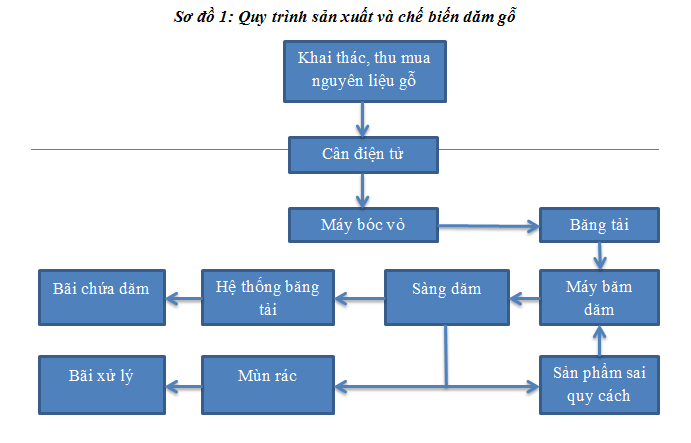

Exploiting or purchasing wood materials

Raw wood is harvested from planted forests or purchased from afforestation households or forestry companies, mainly acacia wood.

Wood used as raw materials is harvested with an age of 4 years or more to ensure the quality of export wood chips. Logged wood with a circumference of ≥ 30cm, can be sold to units or factories producing pallet wood. Wood with a circumference < 30 cm is transported by truck or by waterway to the factory to be used as raw materials for the export process of woodchips .

To measure the input output, all timber trucks will be run through an electronic scale in the export woodchip mill.

Clean the bark of the tree with a 2-axis GREEN MECH peeler

Raw materials are determined in weight by electronic scales and then are taken by a picker or fork truck to a tree peeler to remove the tree according to the standard of chopped wood. After peeling the bark, the raw wood is transported by the conveyor belt to the GREEN MECH wood chipper.

Here, the raw wood will be put into the disc wood chipper to be processed into chips and chips along the conveyor belt to the sieve.

Sorting wood chips and going to the storage yard

The GREEN NECH sorting machine uses a shaker type woodchip sieve to select and classify wood chips:

- Beautiful, right-sized, satisfactory chips will be transferred by the conveyor system to the chipyard.

- Large chips that are not the required size will return to the GREEN MECH wood chipper for processing again into standard sizes and when satisfactory, they will be transferred to the storage yard.

- Sawdust and wood waste that do not meet the requirements will be sent to the disposal site.

-

Export wood chips factory Products from the dumps will be transported and transported by waterway, concentrated at export ports. Through the process of testing the dryness of the chips according to the prescribed standards and agreed between the two parties. Goods will be weighed electronically or drafted and products will be loaded onto large ships to be transported to Japan, Korea, …. or to other countries in the region for the production process.

get a quote CallFor any need for advice, quotation for export woodchip cutting line, please contact Tel (Zalo): 094 110 8888 or kynghexanh.com.vn we will support in the most detailed way.