200kg 2-shaft crusher – Industrial equipment for businesses to effectively crush all kinds of waste, pallets,…

1,200 $ 1,000 $

GREEN MECH, with its long experience in the industry and commitment to providing quality products, is a choice worth considering. With a team of experienced engineers and highly skilled technicians, we ensure to provide customers with high quality 200kg 2-shaft crusher designs that meet the most stringent requirements. In addition, GREEN MECH also undertakes the design of the entire factory line and on-site installation, helping to ensure that the product operates effectively and sustainably.

The choice of a high quality scrap crusher product is an important decision in the material handling and recycling process. The market is offering many options with varying prices and qualities, and finding a trustworthy partner is important.

GREEN MECH, with its long experience in the industry and commitment to providing quality products, is a choice worth considering. With a team of experienced engineers and highly skilled technicians, we ensure to provide customers with high quality 200kg 2-shaft crusher designs that meet the most stringent requirements. In addition, GREEN MECH also undertakes the design of the entire factory line and on-site installation, helping to ensure that the product operates effectively and sustainably.

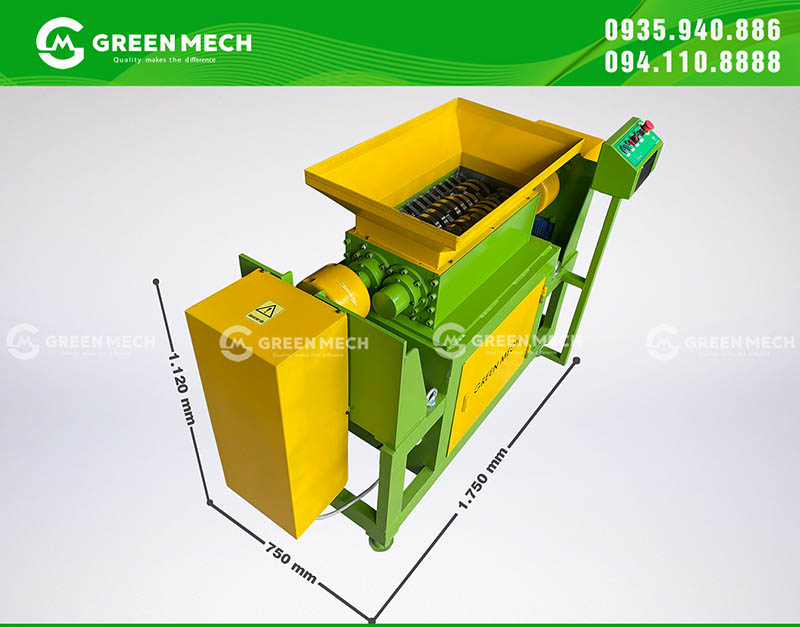

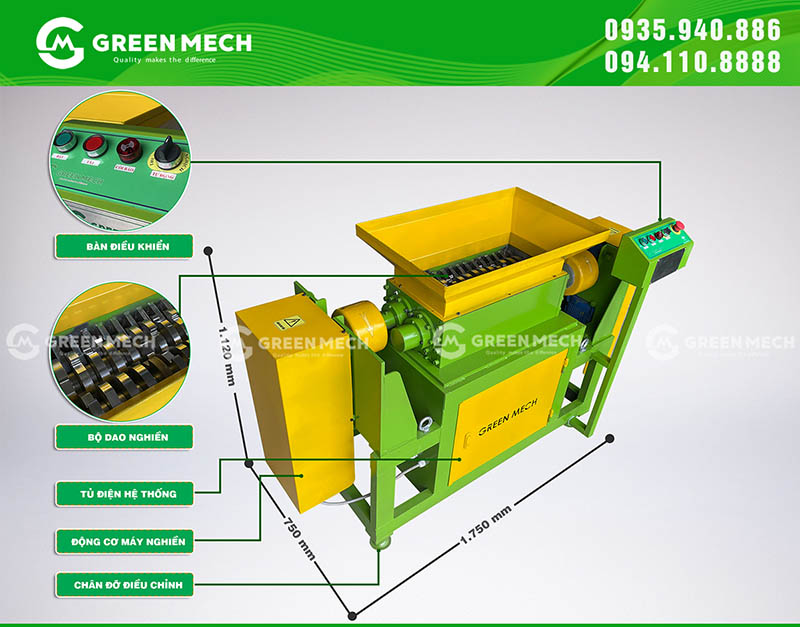

Concept of GREEN MECH’s 200kg 2-roll mill

The 2 shaft crusher is an important piece of equipment in industry, especially in the processing and recycling of waste materials and recyclable materials. With the ability to crush a variety of materials, this machine plays an important role in minimizing waste and optimizing resource use.

The machine has a special design to ensure stable performance and high durability. This is an effective solution for scrap processing and material recycling, helping to reduce production costs and ensure environmental sustainability.

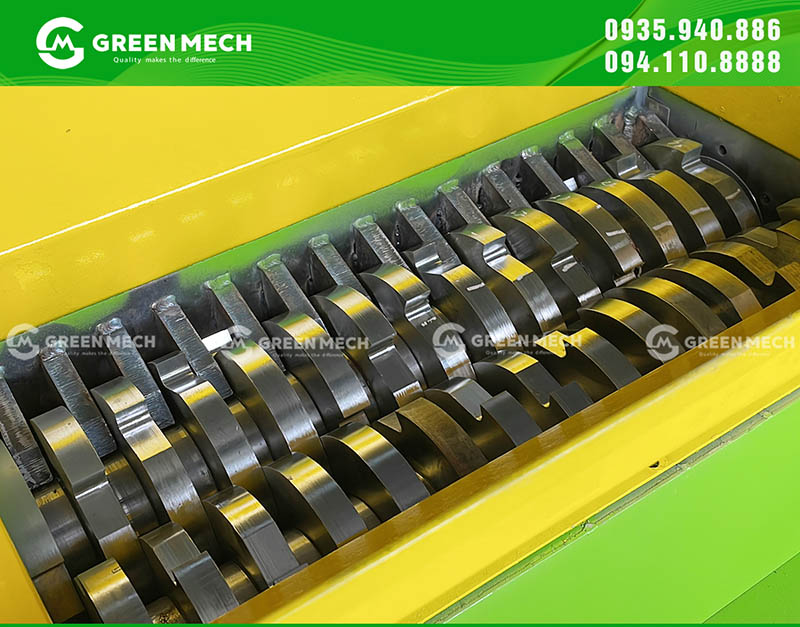

The 200kg capacity 2-shaft crusher is designed with two main shafts, in which the first main shaft has the effect of crushing materials, and the second main shaft has the effect of crushing materials after being crushed by the first main shaft. This facilitates grinding more efficiently and at higher grinding speeds than other types of crushers.

When operating, the crusher uses grinding knives mounted on two main shafts to crush materials. This special design helps the machine have the ability to crush materials that are difficult to crush and at the same time minimizes jamming during operation, ensuring good performance.

All types of materials can be used with 2-roll mills

- Industrial and domestic waste: This includes industrial and domestic waste such as plastic, paper, wood, and many other wastes.

- Types of wood: Wood from trees, trunks, bark, and wood chips from wood mills can be processed with a 2-roll mill.

- Organic waste from biomass: Branches, leaves, straw, corn cobs, wheat, stalks, and garden waste can be ground and recycled.

- Tire waste: Old tires, plastic bottles and other tire products can be crushed and recycled.

- Documents and equipment: Computers, hard drives, documents that do not meet product standards, expired drugs and plastic parts can also be processed with a 2-roll mill.

- Medical and hazardous waste: Medical waste, radioactive materials, and other organic and solid hazardous waste can all be crushed and disposed of safely and effectively.

- Solid metal waste: Paint cans, paint cans, iron drums, scrap metal and scrap aluminum are also on the list of materials that can be processed with a 2-roll crusher.

The 2-roll crusher is a versatile and effective tool for processing and recycling a wide variety of waste and materials, helping to minimize environmental impact and optimize resource use.

Structure of 200kg 2-shaft crusher

- Machine frame: Is a fixed part of the machine, bearing the weight of the entire machine and crushed materials. The machine frame must be firmly designed to ensure stability and safety during operation.

- Grinding shaft set: Includes 2 main shafts with attached grinding knives. The grinding shaft is usually made from high-strength, high-quality steel to withstand strong impacts from the grinding material. The grinding knives on the main shaft help crush and disperse the material.

- Engine system: This is the part that provides power to the machine. The motor is usually an electric motor and controlled by an electronic system. The motor system is responsible for the rotation of the grinding shaft and grinding efficiency.

- Protection system: Protecting the operator and the machine from problems during operation is very important. The protection system includes sensors, indicator lights and other devices to monitor and control safety factors.

- Dust transport and filtration system: This is an important part of the production and material handling process. This system ensures the transportation of crushed products from the machine to where they are needed, and is also responsible for filtering dust and waste particles to ensure a safe and clean working environment.

- Control system: This is the heart of the pallet wood crusher, where the entire machine operation is controlled and monitored. The control system often uses electronic devices such as PLC (Controller Logic Program), HMI (Human Machine Interface) so that the operator can manage and control the machine effectively. Customization of the control system to suit each specific application is very important.

All of these components work together to ensure the pallet wood crusher operates efficiently and safely, and is adaptable to different production needs.

The products are crushed from GREEN MECH 2-roll mill

Contact us for advice and quotes on GREEN MECH industrial 2-shaft crusher

GREEN MECH Vietnam provides a line of 2-shaft crushers and is always ready to advise customers on choosing the right machine and many other types of machines such as GREEN MECH wood crusher, GREEN MECH chopper, knife sharpener, etc. .. with business scale. Using GREEN MECH pellet presses helps optimize wood resources and brings high business efficiency.

For more detailed information and advice about GREEN MECH tablet presses, customers can visit the website: kynghexanh.com or contact Hotline (Zalo): +84 935.940.886 or total number Radio: +84 94.110.8888 to receive support.

How useful was this post?

Click on a star to rate it!

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.

Kỹ Nghệ Xanh Việt Nam –

200kg 2-shaft crusher high quality