Tech news

Industrial dryer price 2024 – Which type should I buy?

The year 2024 will witness the explosion of technology in all fields, and the drying industry is no exception. With the emergence of a series of advanced industrial dryers, businesses and manufacturers are facing many diverse choices.

However, the abundance of designs and features also raises the big question: “Which dryer is really suitable for your needs and budget?” In this article, we will explore the factors that affect the price of industrial dryers in 2024, and at the same time give suggestions to help you choose the most optimal equipment for your production activities.

MỤC LỤC

Current trends in dried food consumption

Popular types of industrial dryers today

Freeze dryer

Technology: Food heat pump dryer use refrigeration technology to keep drying temperatures low, typically between 25°C and 50°C. This process removes moisture without affecting the structure and nutrition of the product.

Working principle: The freeze dryer works by creating a low temperature environment, then dehumidifying the air in the drying chamber, helping the product dry slowly while still retaining its freshness and nutrition.

Advantage:

- Preserves the quality, color, and flavor of the product.

- Suitable for sensitive products such as fruits, vegetables, herbs.

- Energy saving compared to high heat drying methods.

Disadvantages:

- Drying time is longer than other methods.

- High initial investment cost.

- Not suitable for products that require rapid drying or high temperatures.

Convection dryer

Technology: food heat pump dryer uses hot air to dry products, this technology is most popular in the food and agricultural industry. Temperature can be adjusted from 40°C to 100°C or higher.

Working principle: Hot air is blown evenly by the fan through the products on the drying trays, helping water evaporate from the products, making them dry quickly.

Advantage:

- Fast drying time.

- Suitable for a wide variety of products.

- Investment and operating costs are relatively low.

Disadvantages:

- May cause loss of quality, discoloration or loss of flavor of product.

- Not suitable for heat sensitive products.

Freeze Dryer

Technology: Freeze dryers (also known as freeze dryers) use sublimation technology, where water in the product is removed by going directly from the solid (frozen) state to the vapor state without going through the liquid phase.

How it works: The product is frozen at extremely low temperatures, then the pressure is reduced and heat is gently applied. Under these conditions, the water in the product sublimates (changes directly from ice to water vapor) without melting.

Advantage:

- Retains the flavor, color, texture and nutrients of the product.

- Produces a high quality dry product that can be easily reconstituted with water without changing its original properties.

- Longer product shelf life due to very low residual moisture.

Disadvantages:

- Investment and operating costs are very high, due to complex equipment requirements.

- Drying time is longer than other methods.

- Complex technology, high technical and maintenance requirements.

Horizontal dryer

Technology: Horizontal tray dryer uses horizontal drying tray and hot air to dry the product.

Working principle: Air is blown through the product on a horizontal tray, helping the product dry evenly.

Advantage:

- Dry evenly.

- Easy to operate and maintain.

- Large quantities of product can be dried in one batch.

Disadvantages:

- The machine occupies quite a large area.

- Not suitable for large sized products or products requiring low temperature drying.

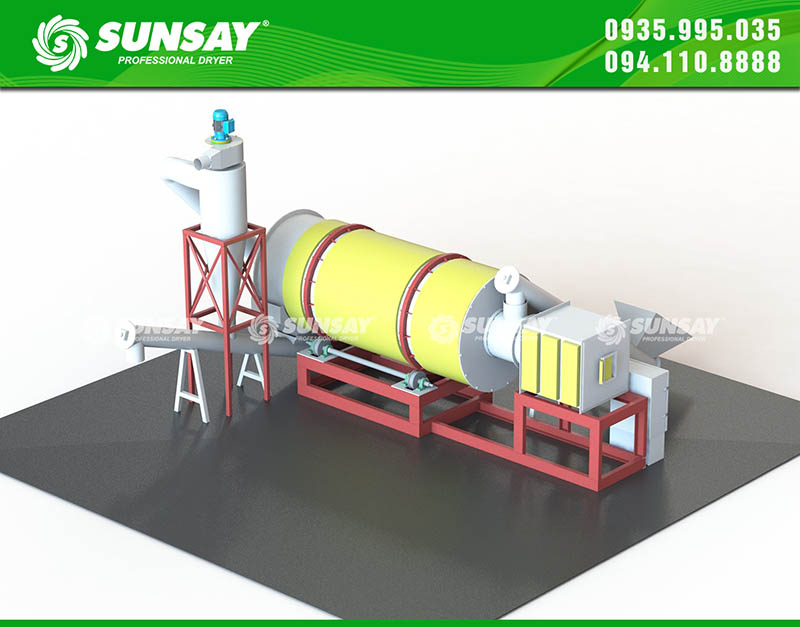

Rotary drum dryer

Technology: Rotary drum dryer uses a large rotating drum to dry the product while the drum rotates, helping the product to be evenly exposed to the heat source.

Working principle: The drum rotates continuously during the drying process, helping the product to be evenly exposed to hot air, while preventing the product from sticking together or drying unevenly.

Advantage:

- Dry evenly in large quantities.

- High automation capability, labor saving.

Disadvantages:

- High energy consumption.

- High investment and operating costs.

- Not suitable for sensitive products or those requiring low temperature drying.

Factors affecting industrial dryer prices in 2024

Technology and features

Advanced technology and modern features are important factors that determine the price of industrial dryers. Dryers that integrate new technologies such as sublimation, freeze-drying, or intelligent automation often have higher prices due to higher research, development, and manufacturing costs.

Size and capacity

The size and capacity of the dryer also greatly affect the price of an industrial dryer. Large capacity dryers, capable of processing large volumes of product in one drying cycle, will be more expensive than smaller machines with lower capacities. The larger the size of the machine, the higher the cost of raw materials and production.

Trademark

Brand is an indispensable factor when it comes to industrial dryer prices. Reputable brands, which have affirmed their quality over many years, often have higher prices thanks to their reliability and good after-sales service. However, this also means that products from these brands are often durable and require little maintenance.

Manufacturing materials

The materials used in the manufacture of the dryer, such as stainless steel, high-grade aluminum, or special heat-resistant materials, also affect the price of industrial dryers. Dryers made from high-quality materials that can withstand harsh environments will cost more but at the same time ensure longevity and safety during use.

Warranty and after-sales service

Long warranty periods, along with good after-sales service, also increase the price of industrial dryers. Customers are often willing to pay more to ensure that they will receive prompt and professional support when the machine has problems.

Which type of industrial dryer should I buy?

Identify specific needs

Before deciding to buy an industrial dryer, you need to clearly identify the type of product you need to dry and the related technical requirements. For example, if you are drying fruits, vegetables or herbs, a freeze dryer or freeze dryer may be the right choice to preserve nutrients and flavor.

Budgeting

Budget is an important deciding factor when choosing to buy an industrial dryer. You need to consider the quality and price of the industrial dryer to ensure an effective investment.

Dryers with advanced technology and modern features often have higher prices, but in return are optimized production processes and high product quality.

For startups or businesses with limited budgets, basic machines can be considered but still meet production requirements.

Choose a reputable brand

Choosing a reputable dryer brand helps ensure quality, durability, and good after-sales service. A reputable brand not only provides quality dryers but also comes with warranty service, technical support, and easy replacement parts.

Evaluation by technical criteria

When choosing a dryer, compare the machines based on technical criteria such as drying technology, efficiency, energy consumption, and maintenance. For example, freeze dryers have superior product quality but high energy consumption and expensive operating costs.

Meanwhile, convection dryers may be more energy efficient but do not preserve nutritional value as well as freeze dryers. Comparing these factors will help you choose the right machine for your needs and production conditions.

Advice from experts

Experts can provide detailed information about the technology, help you better understand the types of dryers and suggest the optimal solution for your specific production needs. They can also assist you in assessing the feasibility of different options, helping you avoid costly mistakes and ensuring that your investment delivers long-term benefits.

Contact and quote

With more than 15 years of research and innovation, SUNSAY’s team of talented engineers has crafted a perfect solution for enhancing the value and preserving Vietnamese agricultural products. SUNSAY not only helps drying become faster and more efficient, but also opens up new opportunities for the sustainable development of the agricultural industry.

With competitive prices and outstanding quality, SUNSAY has affirmed its position as the ideal partner for those who love to improve the quality of agricultural products. SUNSAY’s freeze dryer not only preserves the flavor and nutrition, but also preserves the freshness and appeal of the fruit. Not only that, SUNSAY also demonstrates perfection through the design of the fruit drying factory to meet the growing needs of customers.

Come to SUNSAY to experience our difference and professionalism. We are committed to providing completely free product sample drying services, helping you feel completely secure about the quality and effectiveness of SUNSAY cold dryers. We not only contribute to enhancing the value of Vietnamese agricultural products but also promote the development of the domestic agricultural industry.

For detailed advice, please visit website: kynghexanh.com.vn or immediately contact Hotline (Zalo): +84 935.995.035 or switchboard number: +84 94.110.8888 for support.

Detailed information about the dryer will be updated during the consultation and discussion process. Therefore, don’t hesitate to contact us immediately!