Tech news

Sublimation drying of vegetables, nutrients are still there?

Sublimation drying of vegetables is the method used by mixed rice production units because of its high water absorption capacity without losing the nutritional structure. Despite this, for many users, it is still very unfamiliar with this name. All your questions about this method will be answered in the article below.

MỤC LỤC

What is vegetable sublimation drying? What parts does the dryer include?

Sublimation is not a name for a type of dryer but it is a name for a process of drying from a solid to a vapor without going through a liquid. This is a drying process that is studied through a natural phenomenon, it is born after other drying methods, which also means that this method is more optimal.

Currently, the drying of vegetables by sublimation drying method is receiving the favor of a large number of users. Because this method brings a lot of optimal advantages for users. You will also meet the ability to dry quickly, dry a lot with a variety of products, many different vegetables and fruits. This is an economical solution used by many businesses today because it can be dried effectively with extremely beautiful and quality finished products.

Just find out through the drying process how, surely users also know that this machine is required to have a freezer and a heating unit. With the support of these two mechanisms of action, the sublimation process will go smoothly. The following is detailed information about the structure of the sublimation dryer.

The main parts of the sublimation dryer you need to know?

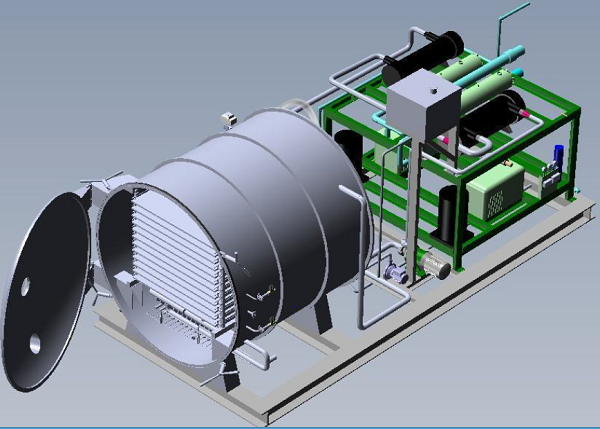

The reason the vegetable sublimation dryer is used a lot and brings practical benefits is because it has optimal and professional design parts. To complement the operating mechanism, the machine will include:

- Sublimation drying chamber

This part is usually made in the form of a closed cylinder, either horizontally or vertically. After being supplied to Dong Thanh, the raw materials will be stored in the sublimation drying chamber. There are four ways to generate heat in the main material: conduction, radiation, using microwaves or high-frequency current.

- Condenser

This part has the main task of condensing the escaping steam and then freezing that steam. Using a comment like this will help reduce the pressure on the vacuum pump.

- Vacuum pump

This part will be responsible for creating a vacuum for the sublimation process to take place. During the drying process, it is also responsible for the top of the volatile components to ensure the operation of the engine.

- Cooling system

This system is required to make the input material at a temperature of up to -30 degrees Celsius. It also cools the condenser to freeze the escaping moisture faster to create a vacuum environment.

The operating capacity of the components in the sublimation dryer will also vary depending on the output power the user wants. For the mini machine for home use, the parts will be reduced but still ensure good functioning.

How is the structure of SUNSAY sublimation dryer?

Structure of SUNSAY sublimation dryer:

✅ Vacuum pressure tank

✅ Heating unit for the product when it is frozen, pumped and heated for the product to perform the sublimation drying process.

✅ Deep negative refrigeration system to freeze the product and keep the water vaporized from the product when it is sublimated.

✅ Vacuum pump ensures a vacuum environment during the drying process.

✅ Electrical system controls the sublimation drying process.

Advantages when choosing sublimation drying method for vegetables

We all know that vegetables are one of the most essential foods for life but it is difficult to preserve. Drying isn’t a new method, but it’s far from perfect because it depletes nutrients.

Using the freeze-drying method has solved this problem. Many studies have proven that freeze drying will retain up to 97% of the nutritional value of vegetables. It is also for this reason that sublimation drying is becoming more and more popular in the market.

SUNSAY – supplier of quality sublimation drying system

As one of the most popular names among consumers today, SUNSAY did not disappoint. When looking to buy sublimation dryer products at the company, customers will receive countless practical benefits and be provided with the best quality product. Specifically, when buying at the company, you will be committed to:

- Always ensure quality products, genuine products

- The most competitive price in the market

- Enthusiastic advice, answer all questions

- Based on the actual needs of customers to choose the most suitable product.

For clear and detailed advice, please call our hotline +84 94.110.8888 . The company’s hotline always responds quickly to all customer inquiries 24/7 to bring you the most useful information.